Modular Design

Thanks to their modular design, our blasting systems can be precisely tailored to the specific application—whether for processing aircraft engine components or for use in medical technology. All components are individually selectable, interchangeable, and serviceable. By cleverly combining proven standard modules with flexibly scalable, customer-specific add-ons, we meet even the most demanding requirements. The result is highly automated, perfectly tuned systems that integrate seamlessly into existing production processes.

ACCESORIES

For a perfect working environment and ideal processes, we individually develop:

- Tooling & Equipment

- Measuring devices for tools and workpieces

- Calibration stations

- Hose monitoring

- Mobile blasting media silos

- Quick-emptying systems for blasting media

- Waste containers

- and more

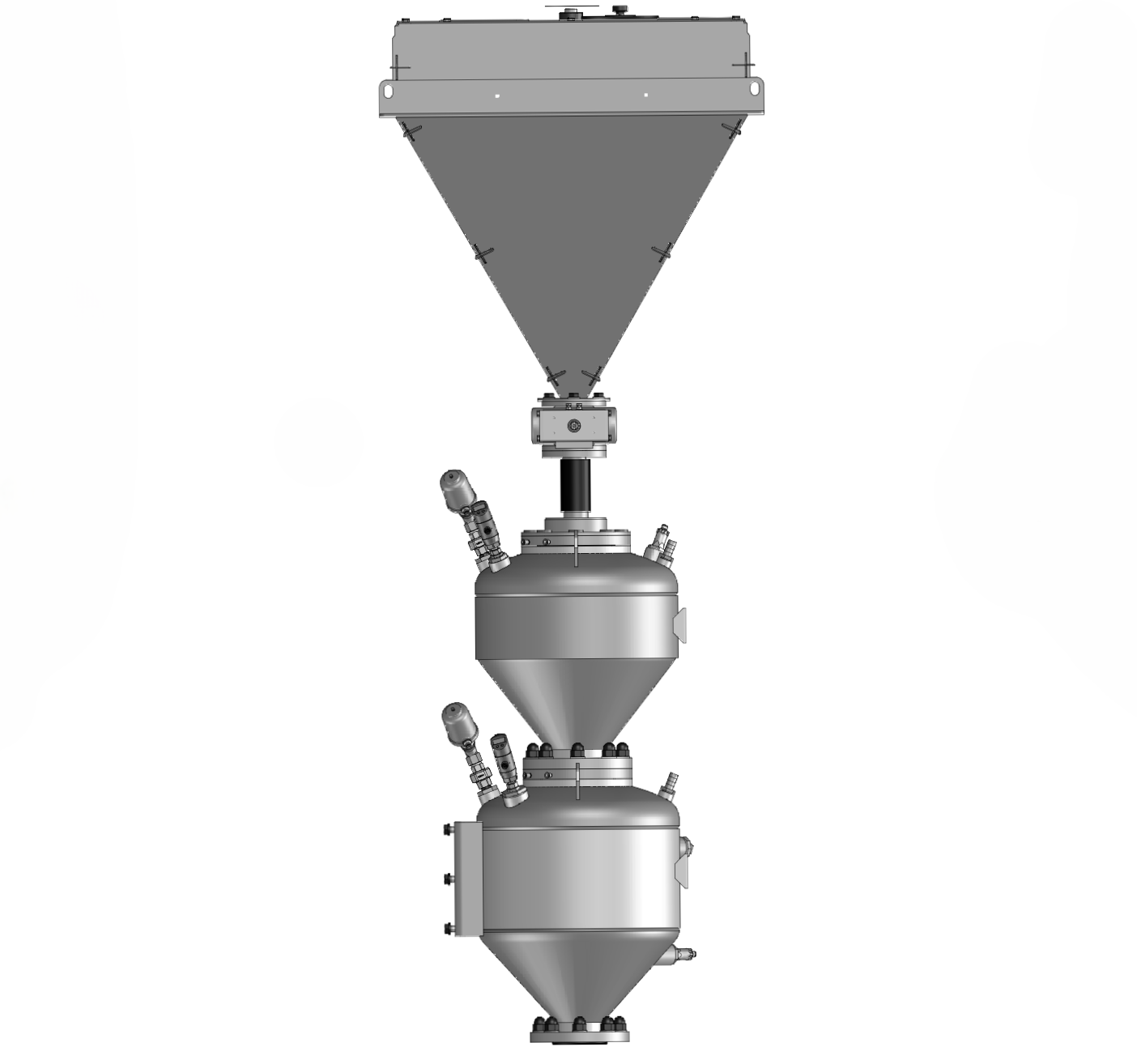

1) Blasting system

Our blasting systems are available in continuous or discontinuous designs and can be flexibly adapted to your process requirements. Optionally integrated, long-life pressure tanks ensure stable operation. The AMS-compliant closed-loop pressure control guarantees precise pressure values in the range of 0.15 to 10 bar.

2) Dosing

The dosing system is a core element of our blasting systems. Multiple different dosing setups can be preconfigured per system, enabling fully automated tool changes. Our AMS-compliant closed-loop flow control operates with an accuracy of ±5%.

- Metallic blasting media (steel beads, cut wire):

- Range FE-large: 1 – 10 kg/min

- Range FE-small: 0.1 – 1.2 kg/min

- Non-metallic blasting media (glass, ceramic, corundum):

- Range FE-large: 0.7 – 7 kg/min

- Range NE-small: 0.4 – 4 kg/min

3) Blasting media recirculation

The blasting media is efficiently collected in hoppers and pneumatically recirculated in a hermetically sealed system. Depending on the requirements, separation is carried out via cyclone or impact separators to ensure a high purity of the blasting media.

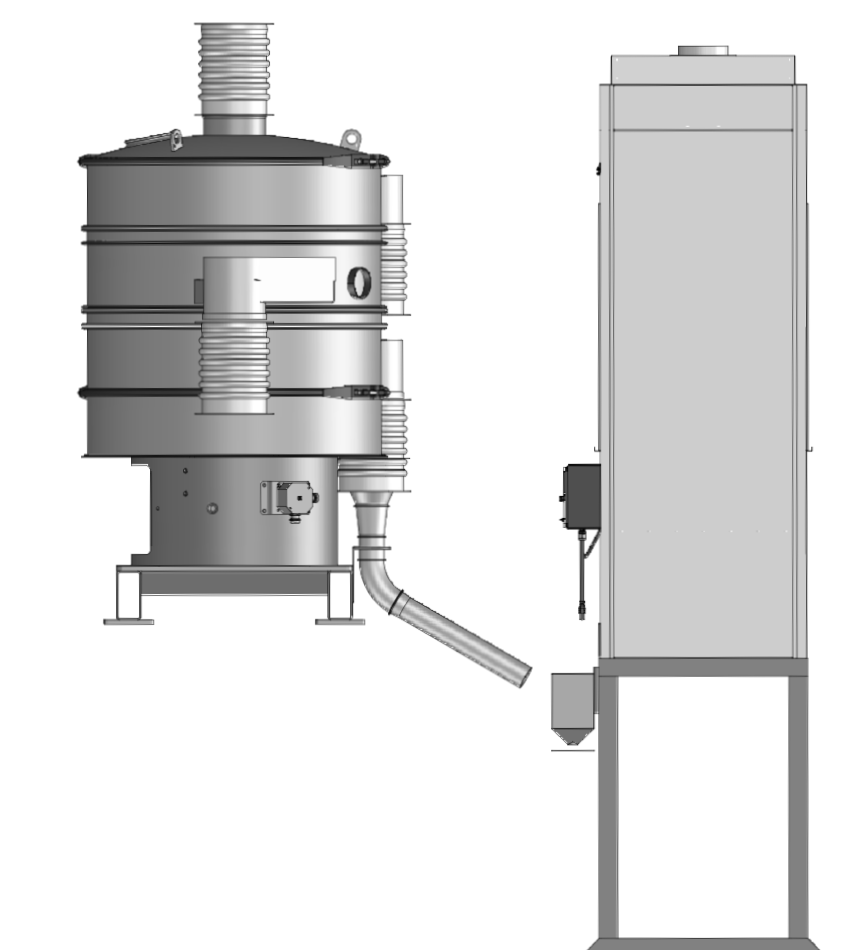

4) Blasting media preparation

Our preparation units combine screening, spiral sorting, and magnetic separation to ensure optimal blasting media quality. This extends the service life of the blasting media and guarantees consistent blasting results.

5) Nozzle movement

For complex blasting processes, we rely on 6-axis industrial robots from leading manufacturers such as Stäubli, ABB, KUKA, or Motoman, optionally equipped with additional axes and protective covers. Alternatively, CNC-controlled linear axes are used, ideal for simple movement profiles in combination with rotary tables.

6) Tools

Our modular tool system includes external, internal, and rotating nozzles as well as ceiling or basement lances. An automatic tool gripper enables seamless switching between different blasting tools without interruption.

7) Workpiece movement

For precise movement of the workpieces, we offer rotary tables, steady rests, shaft blasting devices, as well as satellite and planetary tables. These components are tailored to your specific requirements and ensure optimal workpiece movement during the blasting process.

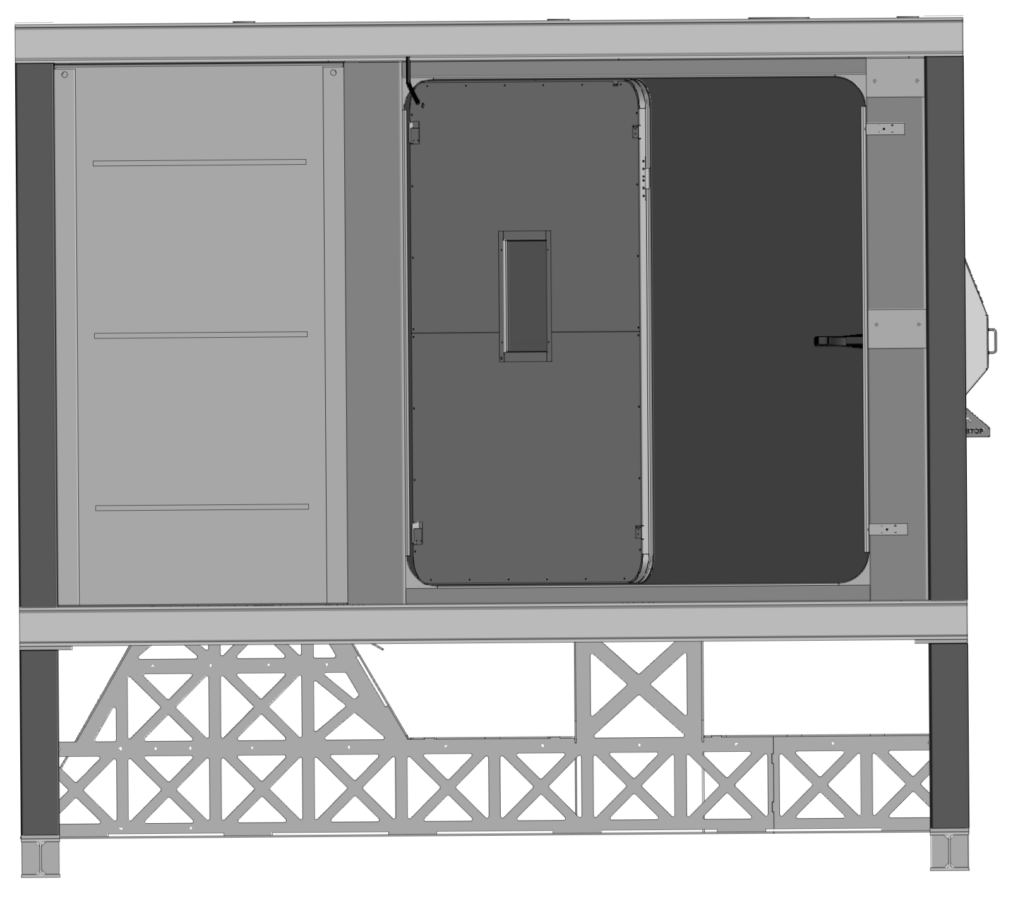

8) Blasting cabin

Our modular, double-walled blasting cabins are constructed to be material- and soundproof, with permanently bonded rubber coatings for maximum durability. Depending on requirements, manual or automatic sliding or hinged doors are available, along with an integrated handheld blasting station.

9) Workpiece handling

For efficient workpiece handling, we offer articulated cranes, crane flaps for overhead cranes, and conveyor systems. These systems enable safe and ergonomic handling of the workpieces.

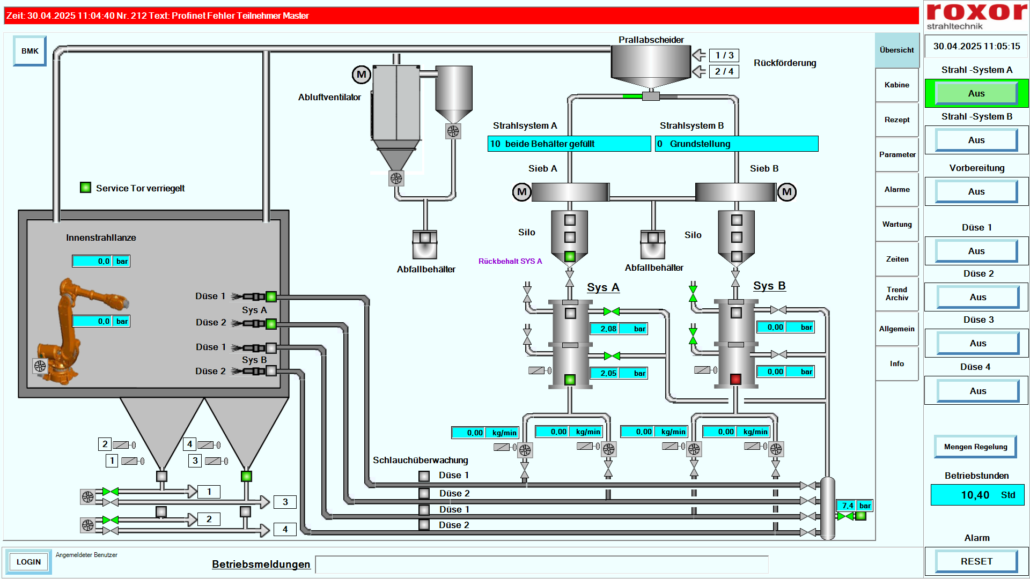

10) Machine operation and control

Our systems are equipped with control and visualization solutions from TBM Automation AG, offering intuitive operation via touch screen. The ergonomically designed, height-adjustable HMI ensures comfortable interaction. Integrated barcode and RFID recognition enable mix-up-proof and process-secure part handling. For complete traceability, processing is logged in accordance with SAE AMS-2432, including all process parameters.

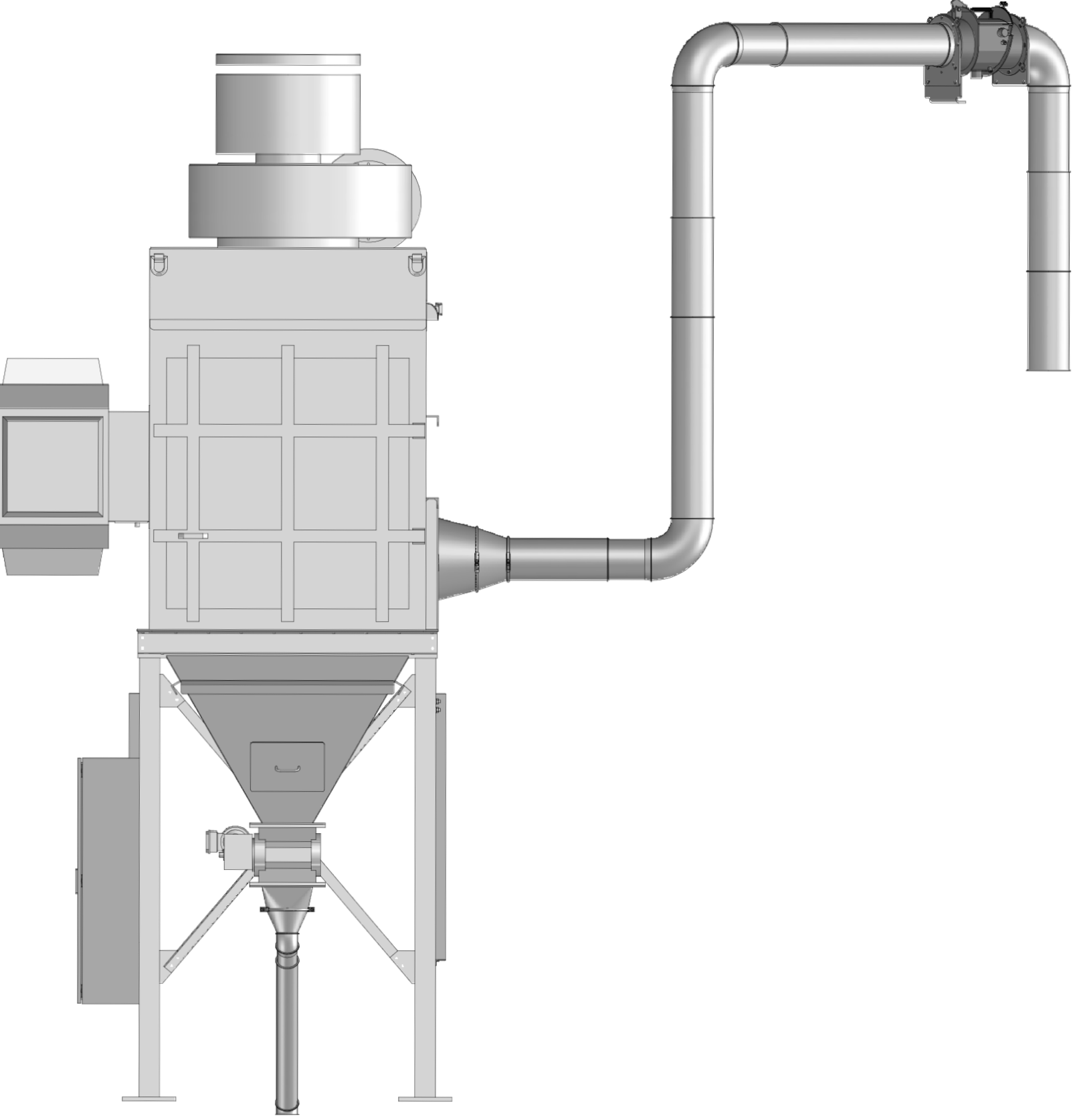

11) Ventilation & Dust extraction

For effective dust extraction, we rely on pre-cleaning using air classifiers or cyclones, as well as dry or wet separation. Our energy-efficient air management system is optionally available in ATEX-compliant design to meet the highest safety standards.